Frequently

Asked Questions

Looking for Kuhns MFG?

We’ve rebranded as Norden MFG! Same ownership, same great products, brand new name.

Browse our frequently asked questions (FAQs).

Equipment

Full size 888 hub: 6″ Bolt Circle, 4.62″ Pilot

Outer Bearing LM67048 – Norden Part #1003640

Outer Bearing Race LM-67010 – Norden Part #1005220

Inner Bearing JL-69349 – Norden Part #1003630

Inner Bearing Race JL-69310 – Norden Part #1005210

Grease Seal AG-GS-25661625SL – G906284 (size 1.625″x2.562″x0.390″) – National # 291099 – Norden Part #1003710

Wheel Hub Cap – drive in style for 6 bolt hubs – 2.446″ O.D. – Norden Part #1003690

Please see the manuals of the legacy AF4 and the Wheel Rakes for those part numbers.

That is only possible with the 8-bale flat models and 10-bale edge models.

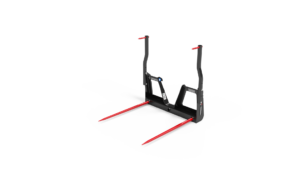

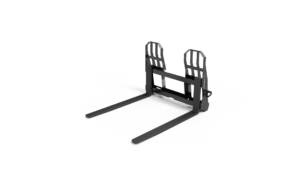

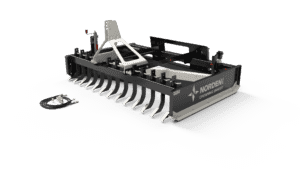

Yes, we can mount pin-style or quick attach brackets or adapters on Norden Mfg tie-grabbers and standard grabbers. The tie-grabbers are designed to be bolt on and the standard grabbers are normally welded on. There 50+ types of loader brackets available.

The longest bale length we have tested is 40 inches. We offer extended models of the Tie-Grabbers and Grabbers to accommodate long bales.

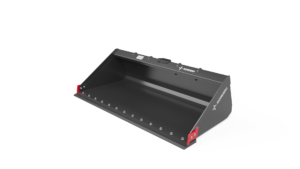

Yes. We prefer to use a dock for loading bundles with a Grabber into tractor-trailer vans. On our farm, we attach the 615 Grabber to a skid steer to drive it in. We find that using the Grabber to arrange 5 bales on edge along one side of the van with the skid steer and hand-stacking 1 bale flat along the other side of the van works very well.

There are many other methods to load a van trailer with the various group sizes. The 18 bale edge and 15 bale flat arrangements fit the trailers best lengthwise and the 10 bale flat arrangement fits crosswise if your bales are not too long.

With the skid steer, you can use the Grabber to stack the bundles into the van until you reach the top layer, at which point you will need to stack the bales by hand to completely fill the van. It works best to build the stack outside of the trailer to the height desired and then push the entire stack into the trailer. If using this method, we recommend using a Tie-Grabber.

There is no extra horsepower required for the Accumulator models. The lift capacity requirements for the Grabbers will vary according to the model.

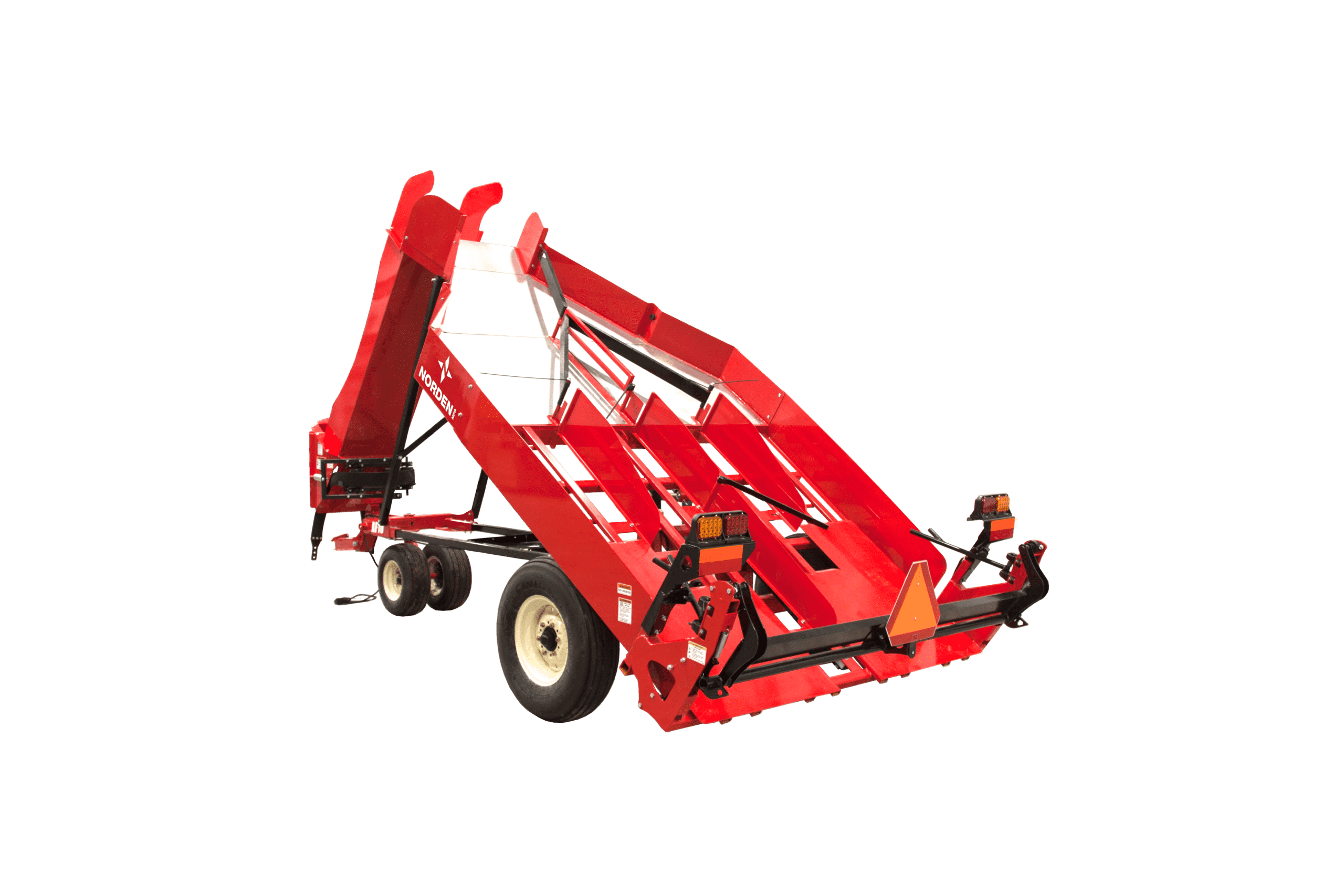

The accumulator is completely mechanical. The last bale of a bundle triggers a switch to release the back gate. The back gate is pushed open by the bales and then gravity swings it shut after they have all slid out.

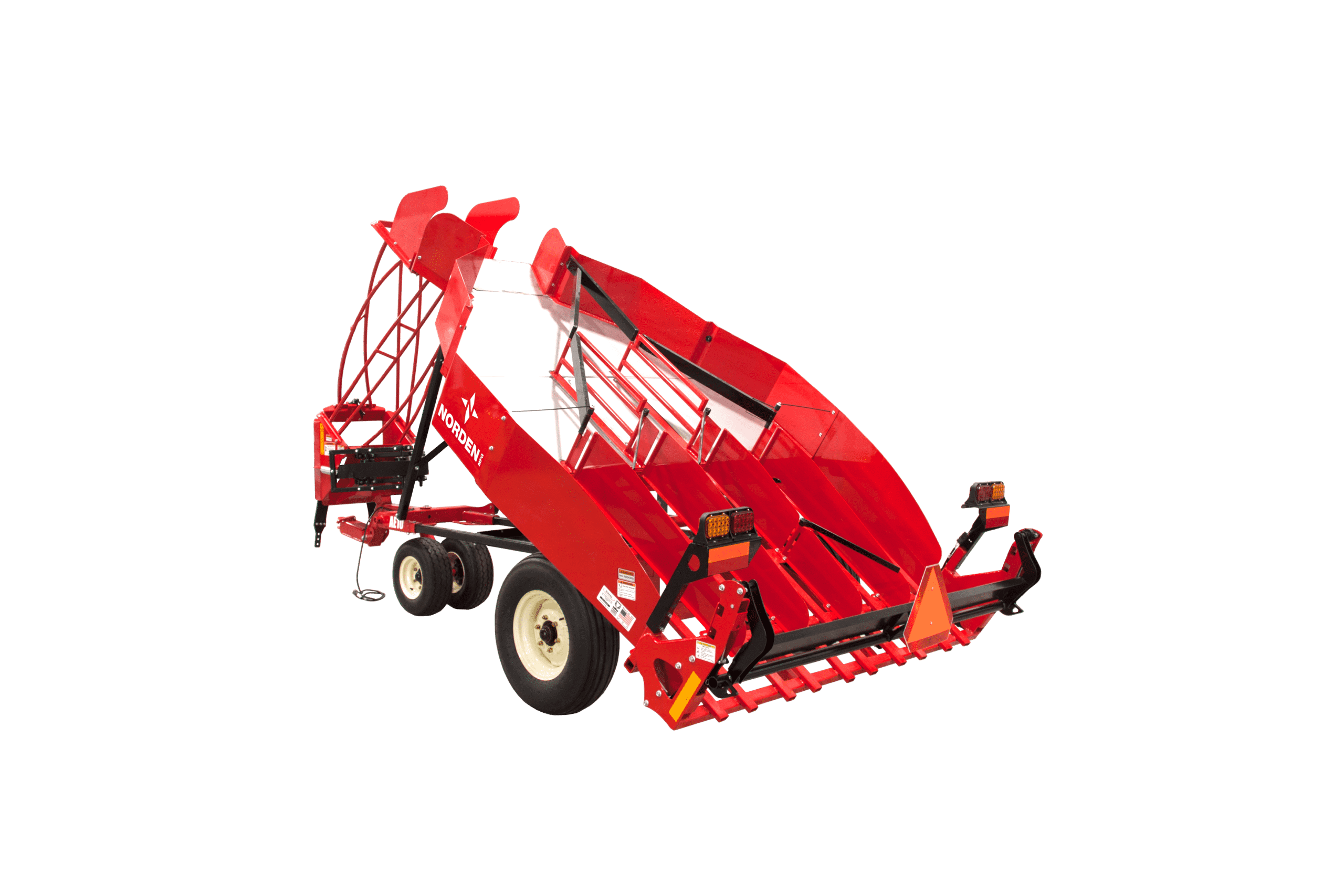

All Accumulator models will fit any 14’ x 18’ baler. The flat bale Accumulator models fit both 14’ x 18’ and 16’ x 18’ balers.

Yes. The Accumulator hooks up directly behind the bale chamber. There are clear instructions in the owner’s manual on how to set up your baler for a Norden accumulator. If you want to look at a manual, you can find them on the Manuals Page

Yes. We offer Accumulator, Tie-Grabber, and Grabber models to accommodate putting the bales on their string sides.

In most cases, yes. Only incredibly steep hills will require adjustments of any kind. The Accumulator is designed with a low center of gravity, and this is lowered even more with a hay load, so it can handle just about any hill that your tractor can. Of course, there is a limit to the slope and the Accumulator has been known to flip when that limit is exceeded.

It takes on average 30 min. to set up a Norden machine after delivery.

Bales

For drying in the stack. Studies have found that hay bales cure much better when stored on their edges. Moisture cannot easily navigate upwards through bales when they are not stored on edge.

If there are any bales still in the chute, using something long and stiff like a broomstick works to push them up and out the chute. If there are any bales left in the lanes, you can manually trip the back gate to open it and release them.

Yes, any 10-bale Accumulator model can.

Keep baling until the un-tied bale comes out the top of the Accumulator’s chute, then simply clean the loose hay off of the Accumulator. Please remember to fix the knotter issue before continuing baling.

Optimize the baler setup. The chamber extension should start the bales up the chute so they are already going up before hitting the bottom of the chute. You may need to lower the front of the baler so that it is level when hooked up to the baling tractor on level ground. Consult your manual for more details.

Rebranding to Norden Mfg.

Kenny Kuhns remains the owner and founder of Kuhns Mfg and now Norden Mfg.

The new logo depicts a compass to reflect the values of Norden Mfg (previously Kuhns Mfg). We truly intend to pursue the truth that is larger than ourselves for the purpose of lifting ourselves and everyone around us to new opportunities and abilities. With a compass as the logo and a name that means “north” in German, we are illustrating our constant path forward.

No, it was a simple name change. We are still the same ownership, same people, same products.

Kuhns Mfg. has often been confused with another great company named Kuhn. Kuhn (without the s) is a great, 200 year old company from France that also manufactures and sells hay equipment. They are much larger than we are. As we continue to grow in our global reach and product lines, we find it necessary to be clear in our branding.

Additionally, the new name highlights the Kuhns family’s German roots as well as our company values. “Norden” is German for “North.” And our brand believes the direction forward is one where the work we do and the decisions we make reflect the coming success and progress of our family, our community, and our entire industry.

The @kuhnsmfg.com addresses will automatically redirect to the matching email recipients at Norden Mfg. To easily reach a member of the Norden team, visit the Contact Us page on this site, or feel free to give us a toll free call at 877.296.5851