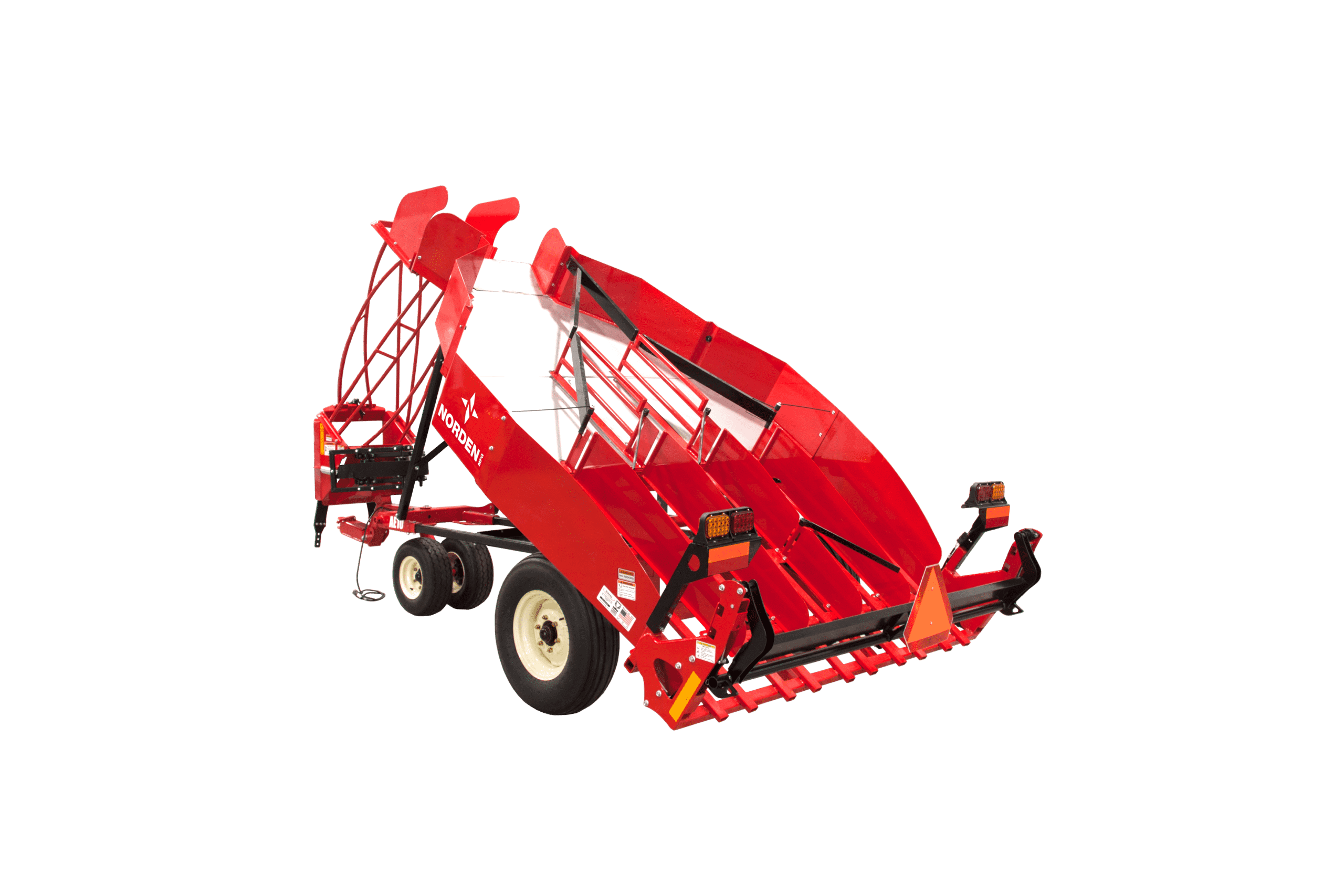

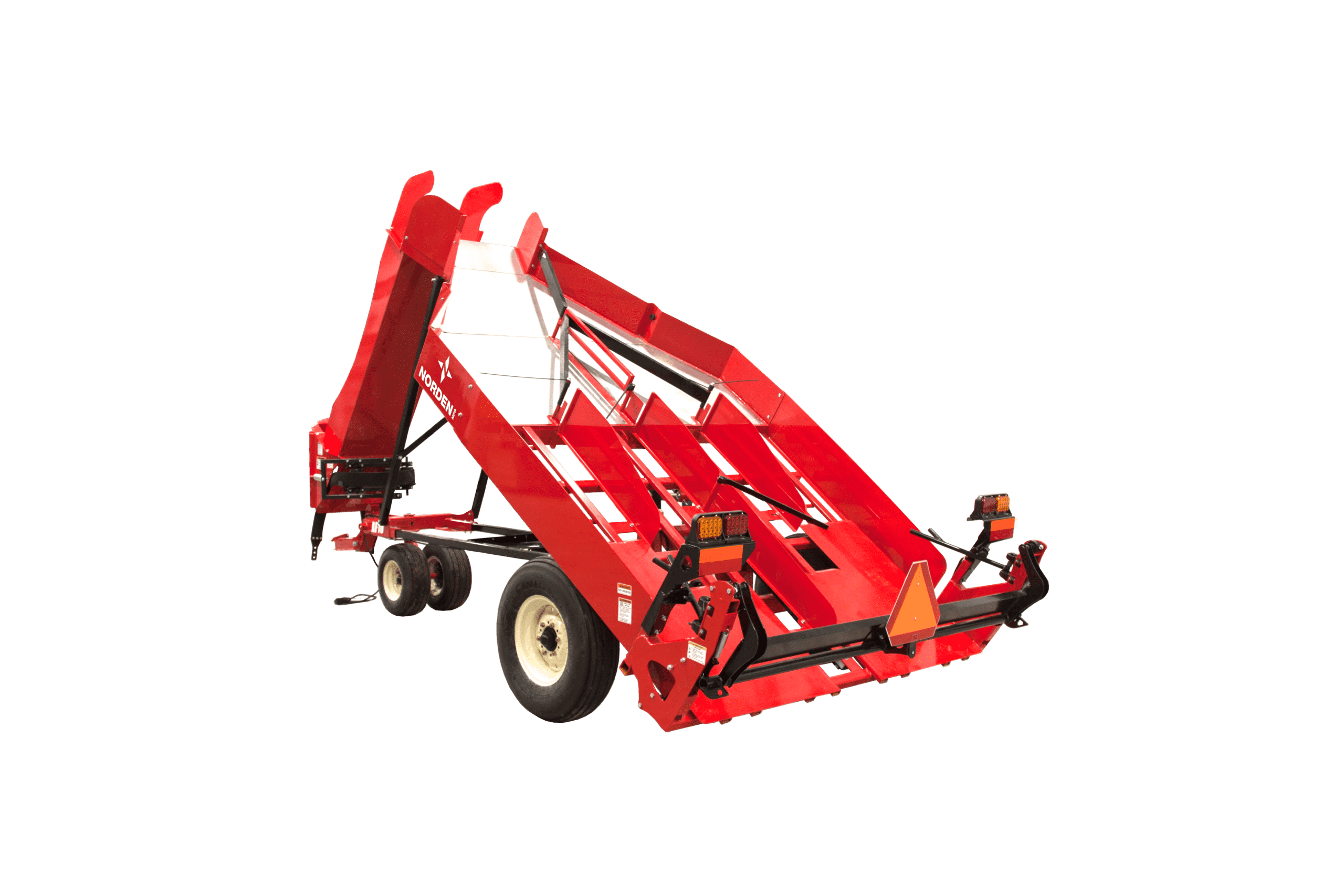

F12 Bale

Accumulator System

Looking for Kuhns MFG?

We’ve rebranded as Norden MFG! Same ownership, same great products, brand new name.

Square Bale Accumulator For 12 Bales Flat

This F12 bale accumulator system is chosen for the fact that the bales are on their strings and still fill an 8.5-foot wagon from side to side. With a touch lower operating weight requirement than the E15, with the same footprint, it is a good compromise. We recommend the F12 bale system for 15,000-30,000 bales per year.

The F12 Accumulator System

- Bales arranged flat with their string side down, 4 bales wide/3 bales long

- Handles bales from 32” to 40” in length

- 12-bale group is well-suited to fill a 20’ wagon

- The bale group dimensions are 72” wide by 96”- 120” long

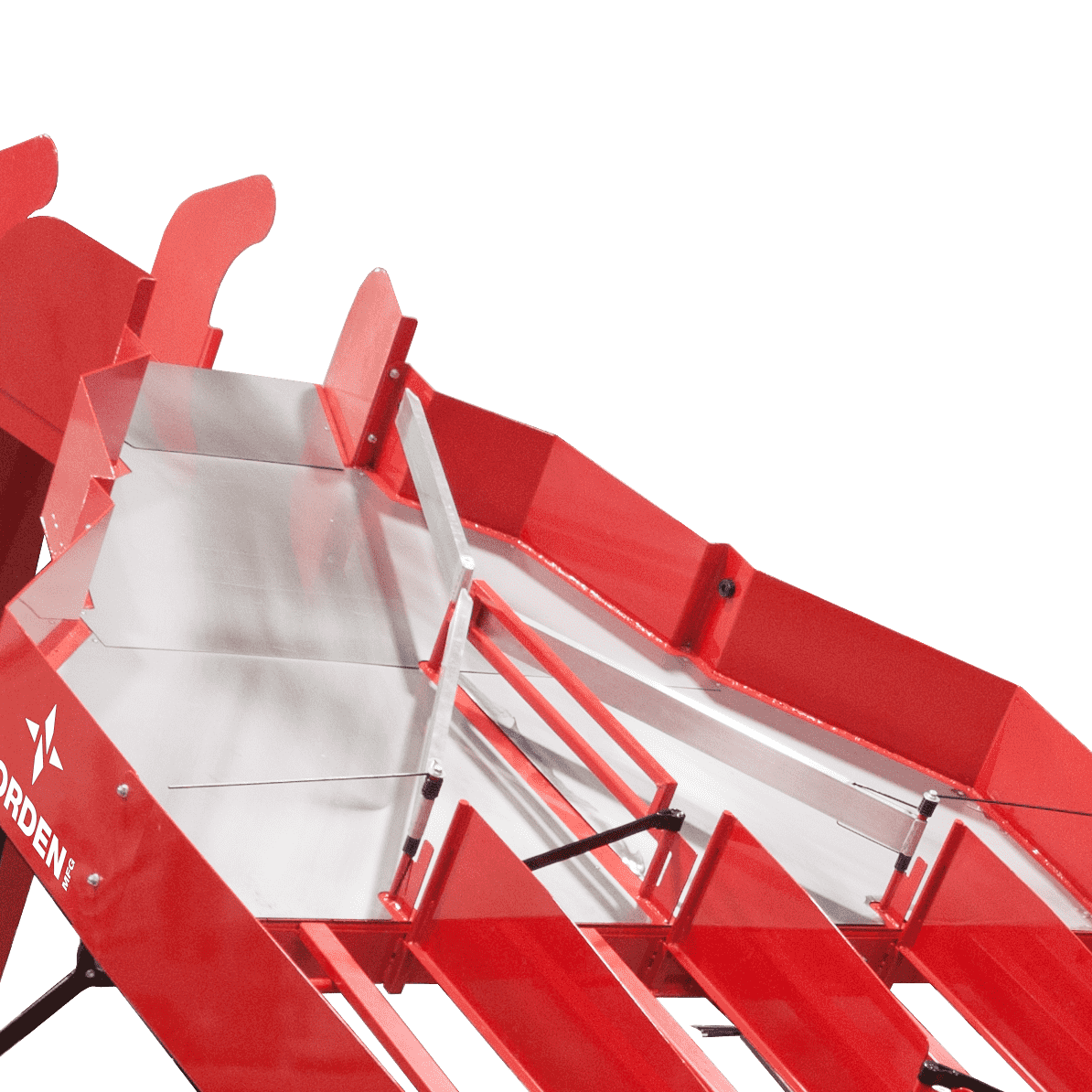

Straight Chute

The straight chute allows each bale to stay flat on its strings, while the baler provides the force needed to push the bales to the top of the chute.

Stainless Steel Deck

The stainless steel deck provides a better surface for the bales to slide in higher dirt and moisture conditions.

Gravity-Driven Gates and Final Bale Lever

As gravity moves the bales downward, the last bale in each row swings a gate to open the next row. The last bale in the grab opens the back gate.

Automatic Back Gate

The last bale in the grab opens the back gate. As the accumulator unloads itself, springs automatically return all the gates back to their starting position, and the rear gate snaps back shut, ready for the next bale.

Bale Configuration

4 Bales Wide and 3 Bales Long

Group Dimensions

72” Wide and 96” to 120” Long

Approximate Weight

2,290 lbs.

Working Height

11 ft. 1 in.

Working Length

21 ft. 1 in.

Working Width

7 ft. 10 in.

Bale Handlers

For the F12 Accumulator System

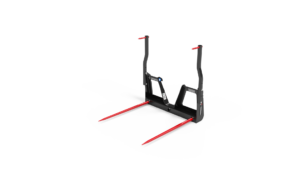

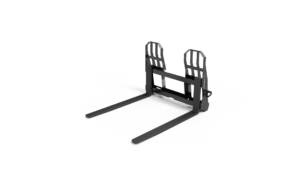

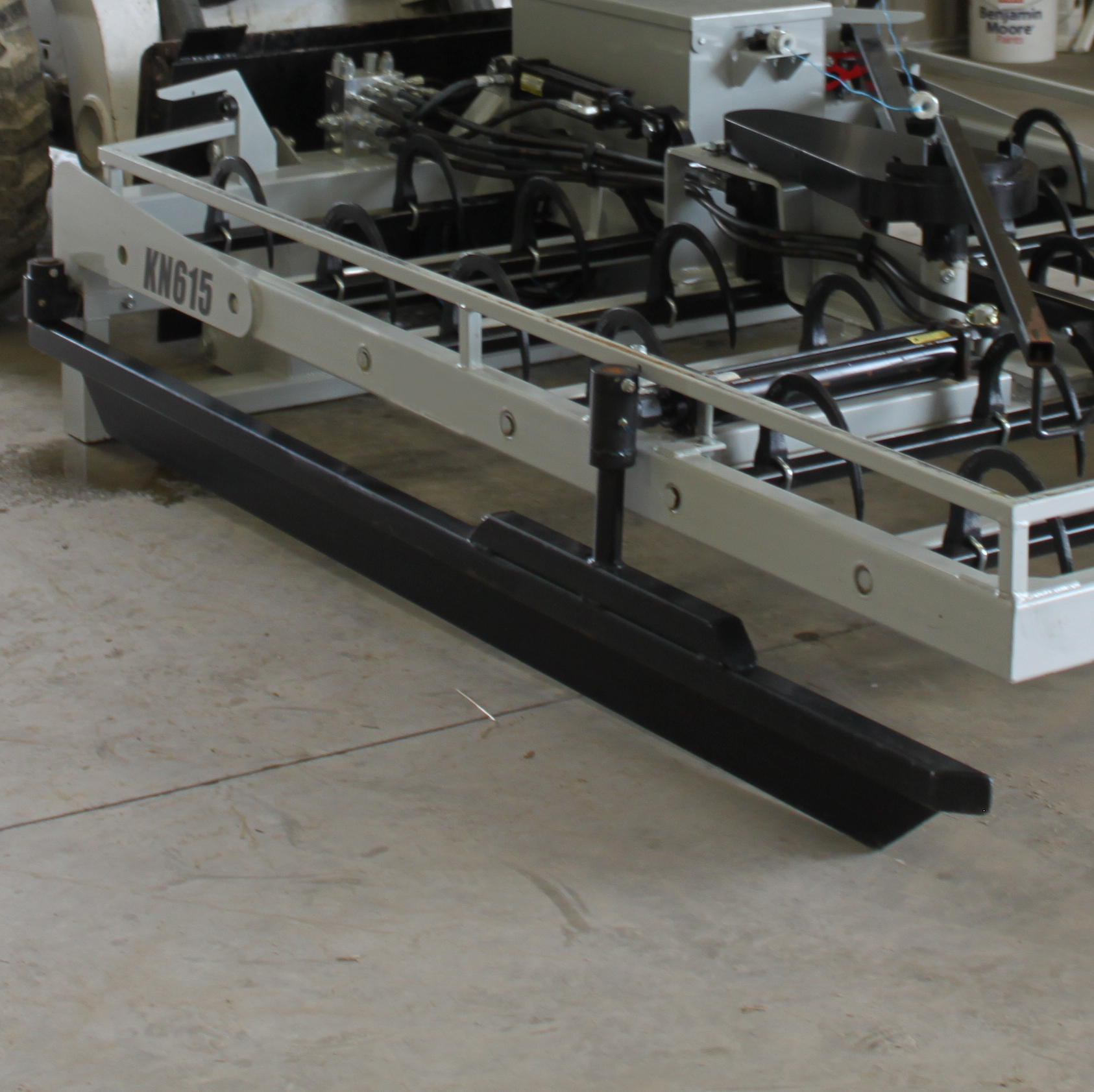

612F Grabber

- For moving and grabbing 12-bale bundles with the bales flat on the strings.

- The group arrangement fills a 20’ wagon front to back and is able to fill an 8.5-foot wide wagon or trailer.

- Requires a loader with at least 1,800lb lift capacity and one set of remotes.

Cast steel bale hooks

Once the group is tight, a single hydraulic cylinder rotates all the hooks simultaneously into the top of the bales to pick up the group. These durable hooks allow for 2 hooks per bale to ensure the bundle is secure while transporting bundles.

Detailed Specs

Bale Configuration

4 Bales Wide and 3 Bales Long

Bundle Dimensions

72” Wide by 96” to 108” Long

Required Loader Capacity

1,800 lbs.

Working Height

1 ft. 1 in.

Working Length

7 ft. 11 in.

Working Width

6 ft. 0 in.

Approximate Weight

760 lbs.

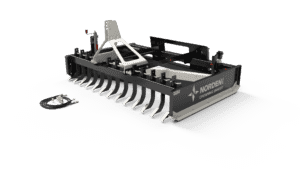

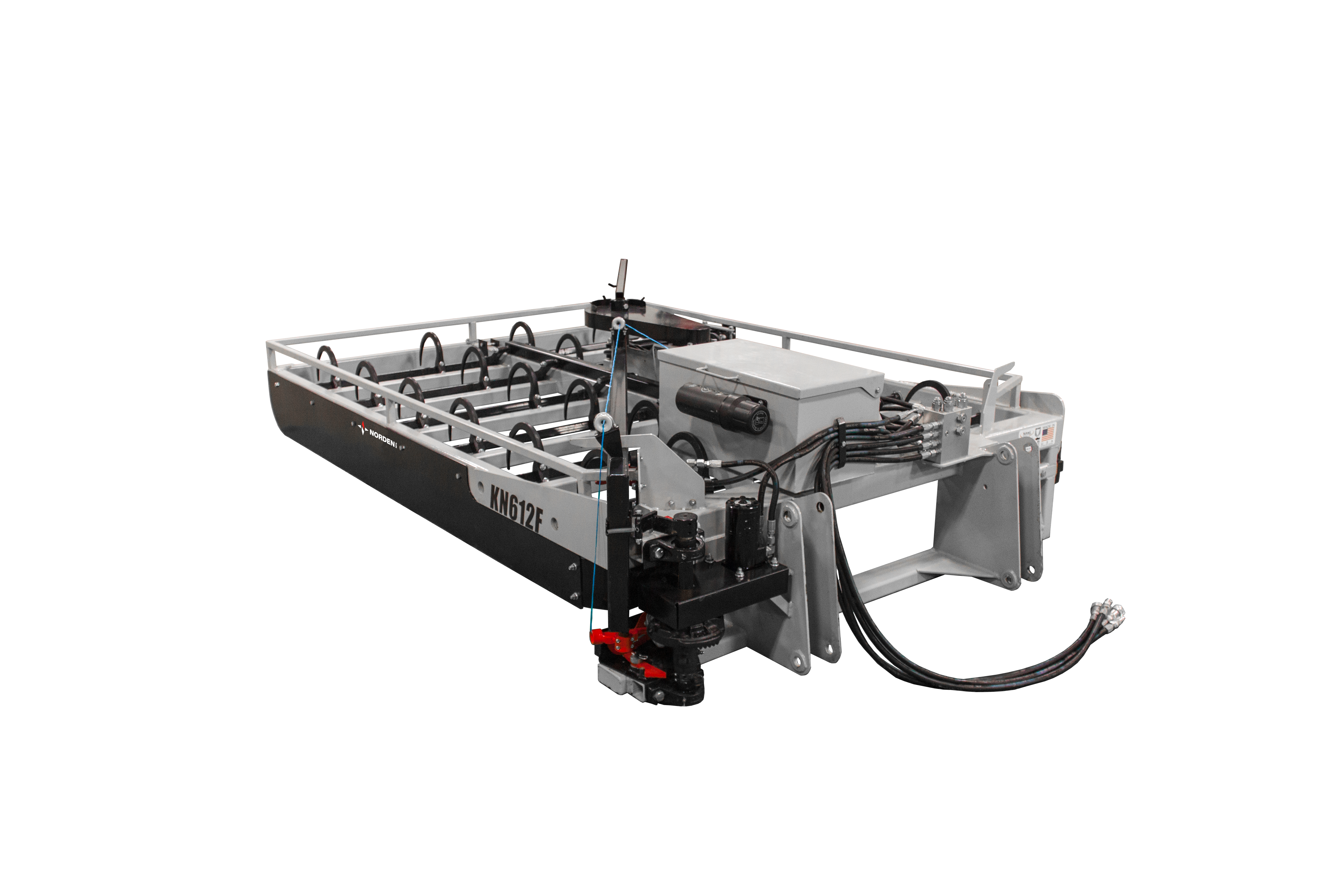

KN612F Tie-Grabber

- The KN612F Tie-Grabber picks up and ties bales that are arranged by the AF12 bale accumulator. Four wide, three long, flat on strings.

- Configuration can fill a 20’ wagon lengthwise and the three bales long fit on an 8.5-foot wide wagon or trailer.

- Requires a loader with at least 2,300lb lift capacity, see details for hydraulic requirements

Squeeze Arm

Once the machine is aligned with the bale bundle, the Squeeze Arm applies pressure and squeezes the bales tightly together to form a strong and compact bundle. This arm is important for creating a bundle that is easy to stack, move, and load.

Loader Mount

This customizable option allows you the flexibility to move between multiple loader hookups.

Twine Arm

When hydraulically engaged, the twine arm wraps twine around the bundle of bales to hold the bundle together.

Detailed Specs

Bale Configuration

4 Bales Wide and 3 Bales Long

Bundle Dimensions

72” Wide by 96” to 108” Long

Required Loader Capacity

2,300 lbs.

Working Height

2 ft. 6 in.

Working Length

7 ft. 11 in.

Working Width

6 ft. 0 in.

Approximate Weight

1,460 lbs.

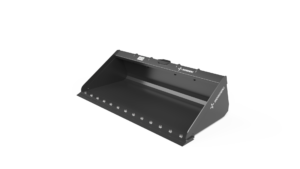

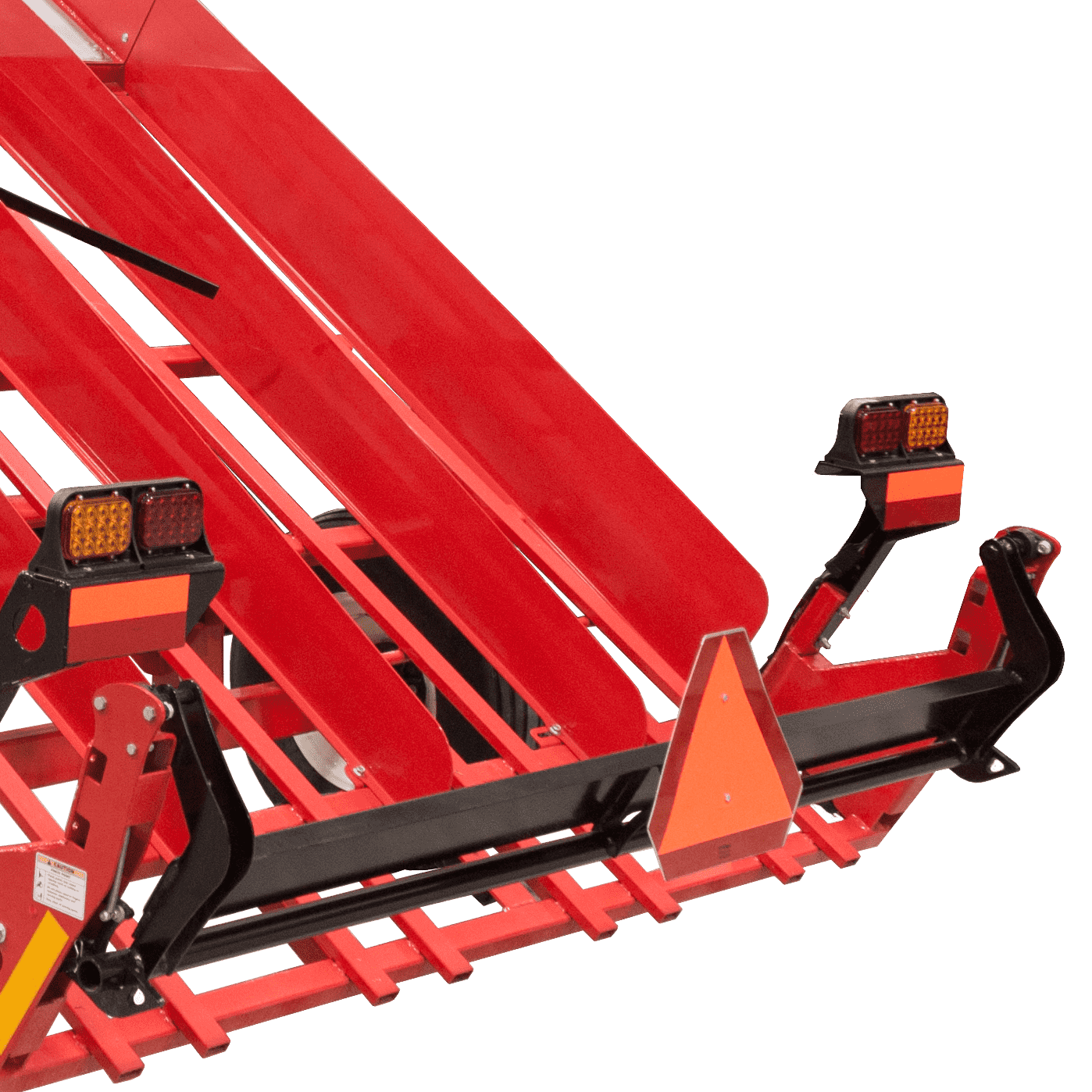

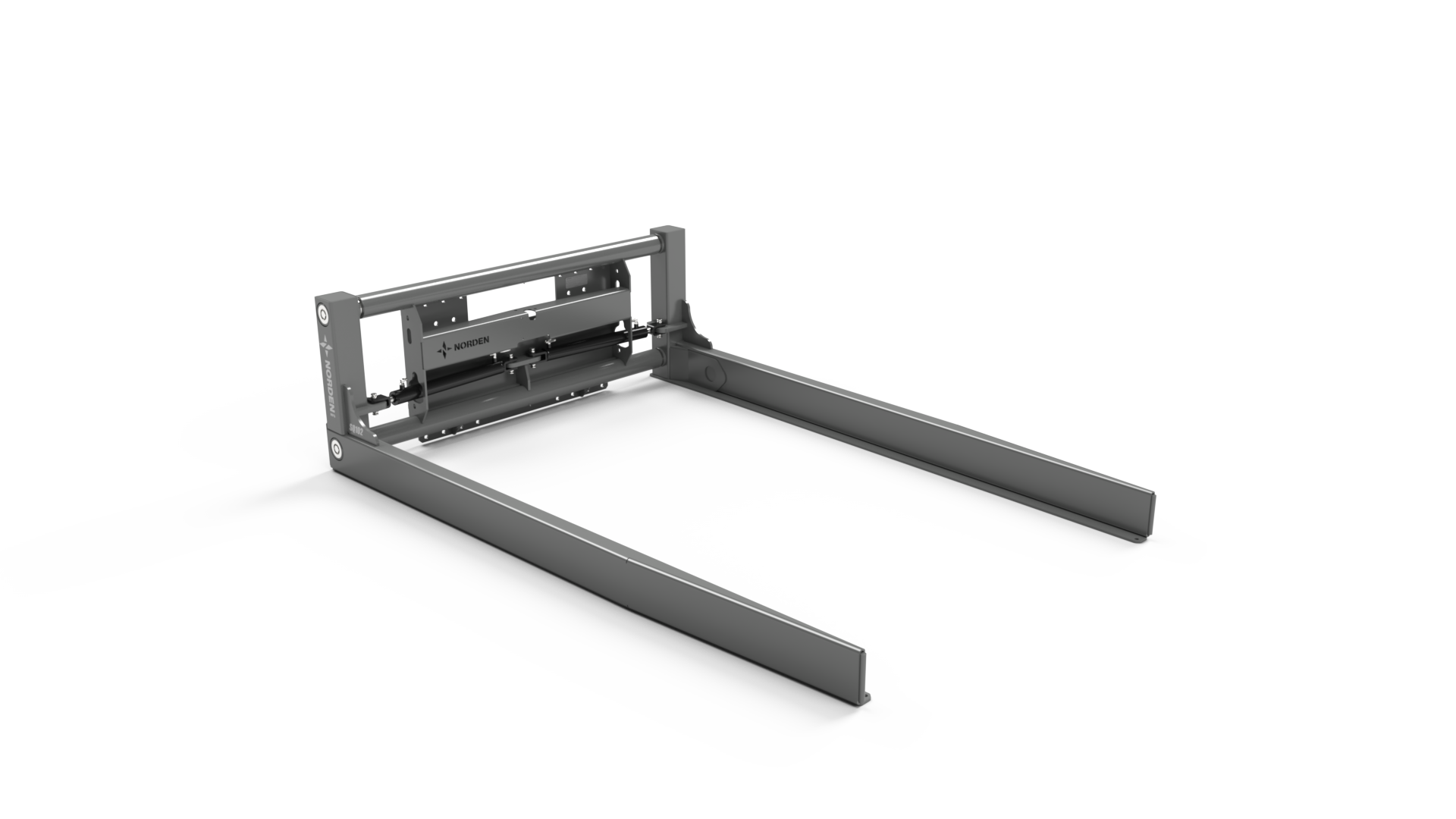

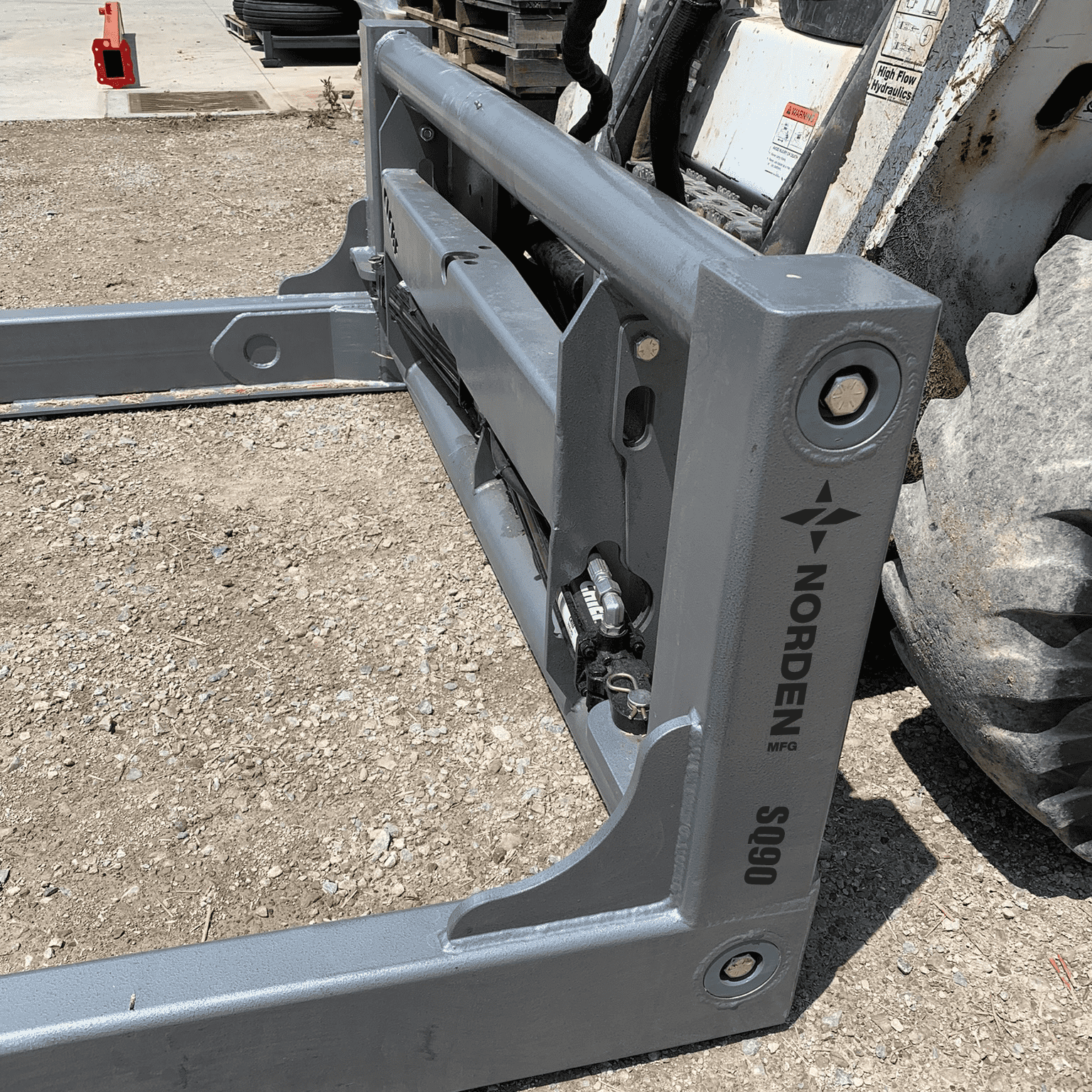

Sq102 Bale Squeeze

- Picks up tied bundles that are 4, 5, or 6 bales wide and 3 bales long.

- Inside length of 101 inches.

- For maximum efficiency, it is recommended to pick up as many bales as the loader can safely handle.

- Has a maximum lifting capacity of 4000 pounds.

- Weighs 1,060 pounds without the loader bracket.

- Works with E18, E15, F15, and F12 bale packs.

STRONG WHERE NEEDED

Designed and built with precision, this squeeze maximizes lifting capacity while providing the necessary strength. Developed in collaboration with the experts at Clerf, upgrade your operation and experience effortless bale handling today.

MOVE MANY BALES IN A SHORT ORDER

Moving multiple tied layers of bales in a single move will save you the maximum amount of time. Capable of handling up to 4,000 lbs., this squeeze allows you to move up to eighty, 50 lb. bales at once, streamlining your operations and increasing productivity. The only question is if your loader can take it.

Detailed Specs

Shipping Dimensions

107” L x 74” W x 29” H

Working Dimensions

101” L x 67.5-103.5” W x 29” H

Approximate Weight

1,060 lbs.

Group Size

72-90” W x 101-108” L

Maximum Lifting Capacity

4,000 lbs.

Bale Packs

F12, F15, E15 and E18